Fixed Cone Valve is a valve suitable for high water head, high flow rate working condition, working without vibration and cavitation. Commonly used in the following system:

1. Turbine set fault discharge valve (Bypass free discharge valve)

2. Dam vent discharge valve

3. Reservoir water supply pipe flow adjusting valve

4. Tap water supply system different area pressure adjusting valve

5. Especially suitable for the safety discharge of 0 backpressure, high flow rate pipe system

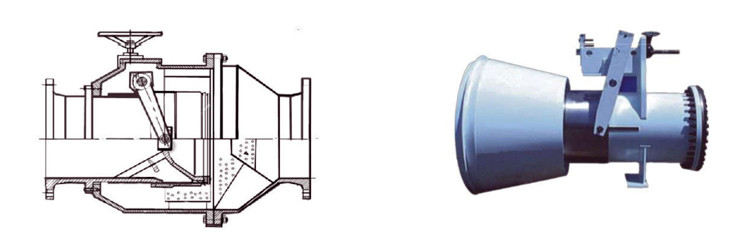

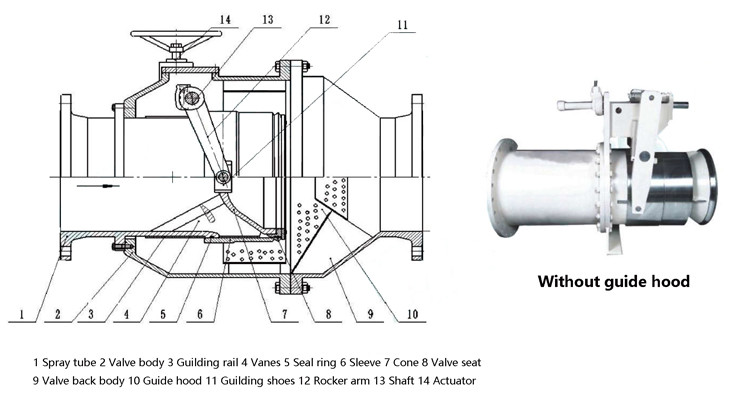

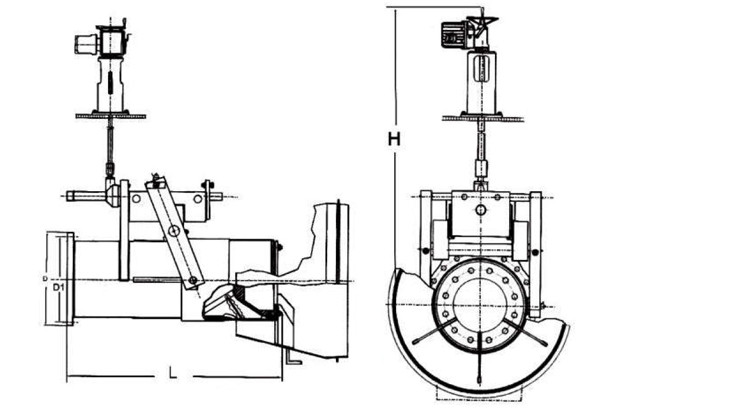

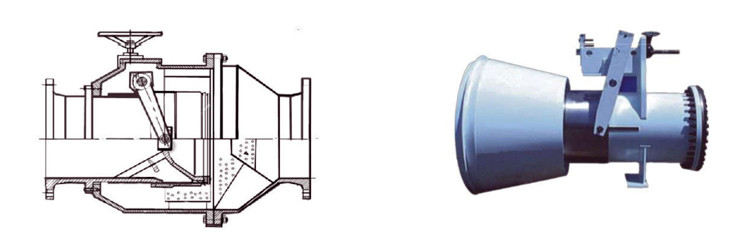

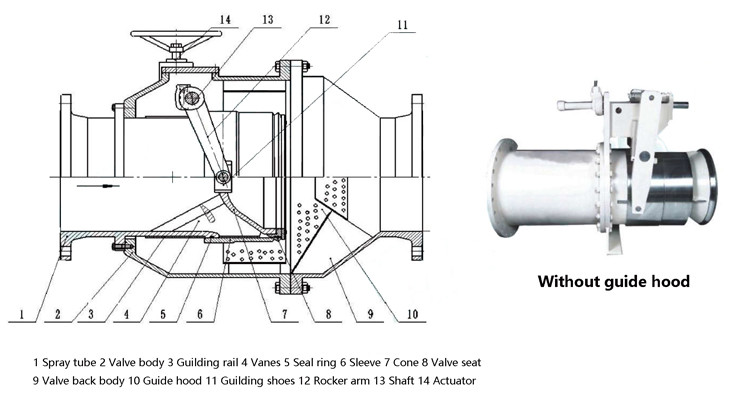

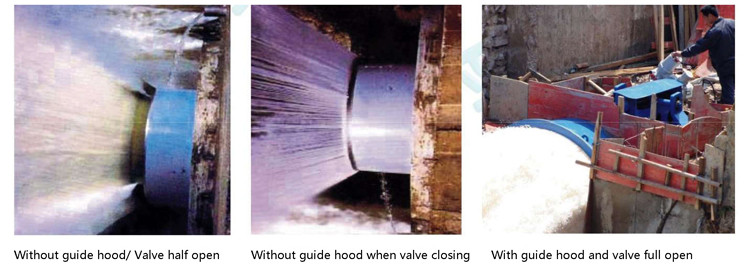

Fixed cone valve is mainly composed of spray tube, cone, sleeve, valve seat, guide hood, actuator and so on. Spray tube and cone are connected by vanes. There is open distance without wall between spray tube and cone, sleeve is installed outside spray tube, valve degree is adjusted by the sleeve axial movement Guide hood could be installed at the exit of valve, guide hood could change the status of output water. Valve is adjusted and controlled by actuator.

Cone valve has two structure types: Middle pipe type and discharge type. Middle pipe type is installed in the middle of pipe, to cut off, reduce pressure and control flow rate. Normally middle pipe type is installed with guide hood, to avoid the cavitation of the pipe behind valve. Discharge type is installed at the end of pipe, to discharge, sustain pressure and control water level.

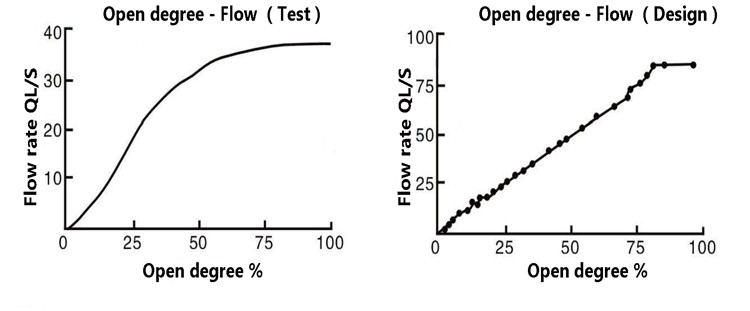

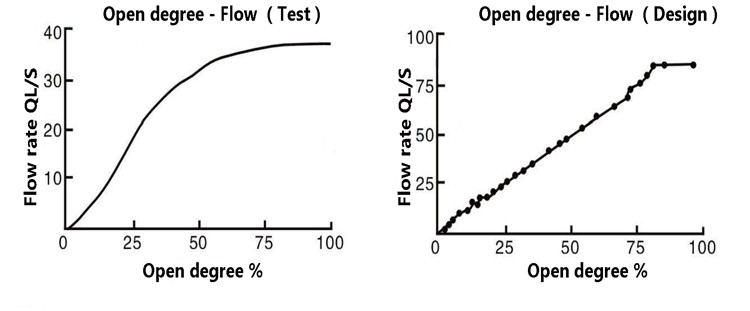

Valve open degree and discharge flow has a linear proportional relationship , could achieve precise controlling and adjusting

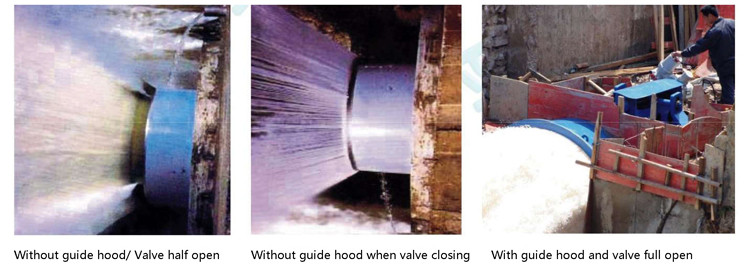

Good energy dissipation function: Fixed cone valve is made with a cone designed conforming to the characteristics of fluid mechanics. Cone is supported by vanes, when discharging, water will diffuse at cone angle, and decompose into thin spray form , water will atomize when frict with air, achieve excellent energy dissipation function.

In valve with guide hood, water is spray out from holes, water collided with each other, speed energy mostly disappeared, it could protect downstream pipe, building from striking.

Excellent anti-cavitation function: In valve, if the flow status changes, small high pressure bubble will be generated, if these bubbles breaks on the surface of valve or pipe, it will produce high instantaneous impact energy, will damage valve and pipe. It is what we called cavitation. In fixed cone valve, when water flows through the space between cone and sleeve, flow speed is high, pressure is low, high pressure bubble will be produced. Water will bubble speed flow rate falls sharply, pressure increases, bubble will break. Guide hood adopts advanced hydraulic design structure, There will always be a fluid flow back to guide hood and fixed cone periphery, to stop the bubble from attaching to the valve and pipe, to break valve in circulation water flow, protect valve from cavitation.

Small operation torque: In fixed cone valve , water pressure only produce radial pressure on the sleeve. Valve operation torque, and water pressure changing will not affect operation torque.

1.Slight vibration.

2.Special floating valve seat and metal seal design, ensure perfect sealing and long service life.

3.Low flow resistance loss. Design resistance coefficient is 0.5(without guide hood) or 1.4 (With guide hood)