Search This Supplers Products:ValvesPipePipe fittingsElectrical conduitConduit fittings

HS Series Cast Iron Motorized Water Flow Control Plunger Valve

- group name

- Flow Control Valve

- Min Order

- 1 piece

- brand name

- GARLOS

- model

- HS340H/HS940H

- update time

- Tue, 13 Jun 2017 12:08:52 GMT

Paramtents

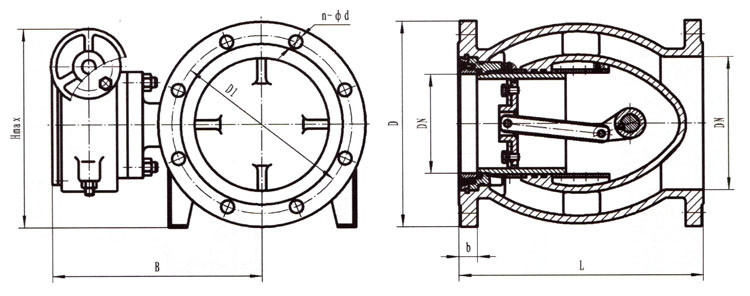

Flow path Straight

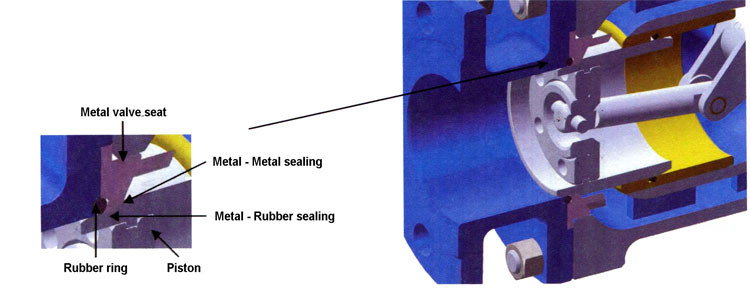

Sealing Metal-metal/ Metal-rubber

End connection Flange

Actuator Manual/ Electric

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

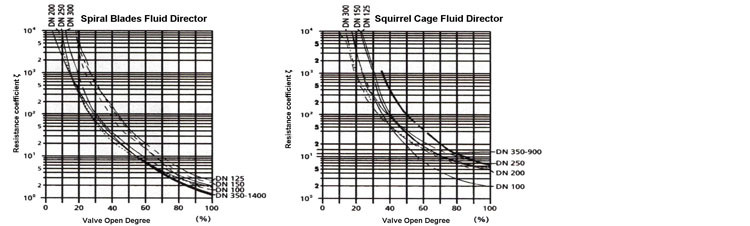

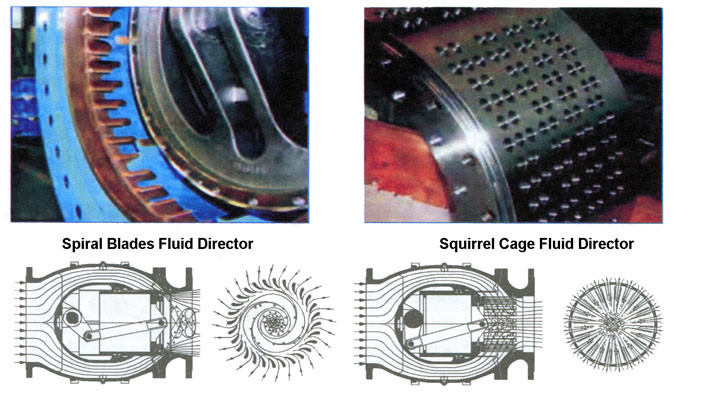

1 Pressure reducing

Pressure reducing range is large, single stage valve can reduce pressure from 6.3MPa to 1.0 MPa, no cavitation, no running noise. In the high water head hydropower station, water from the pressure pipe, can be supplied to low-pressure water supply system after the pressure reducing of this valve.

2 Reservoir water level regulation and sand washing

When discharged into the atmosphere, the water stream first shrinks and then diffuses at a wide cone angle and breaks down into a thin sprayed state. If suppression of water flow is required, a beam device may be installed, which not only mixes air and water but also concentrates the flow.

3 Pressure relief,

It can be used as large water turbine bypass pipe discharge valve. When water turbine has a accident, the main valve is closed, piston type control valve will open automatically to eliminate the harm of the water hammer to the system.

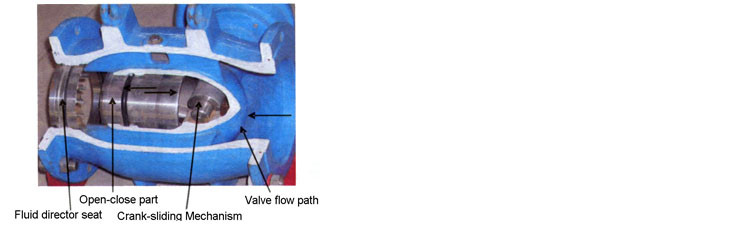

4 Flow control and cut-off

In the fully open to fully closed stroke, the valve flow coefficient and valve opening have linear relationship. Even in the fully closed to 10% opening stroke, still has a good flow control effect. The valve can also cut off the flow channel, play the role of gate valve, globe valve and so on, with good sealing performance.