A. High valve rigidity: the valve body is spherical, valve core is overall eccentric crankshaft structure,the valve can adapt to high flow rate and large flow working conditions. In the small opening high-pressure difference working conditions, the valve can be without vibration, without noise.

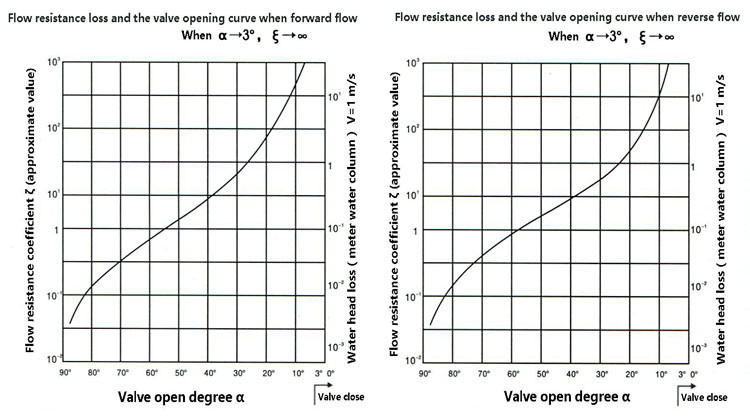

B. Valve flow path is straight structure and full-bore design, large flow area, flow resistance is small.Opening and closing structure can meet with two-way flow requirements. When the valve is fully open, valve body flow channel is similar to a straight pipe,regardless of water supply system forward or reverse run, water resistance coefficient is less than 0.1. When valve opening in the 150-850 degree, water head loss and open degree is basically a curve, can accurately adjust the flow.(See water head loss and water head loss coefficient curves).

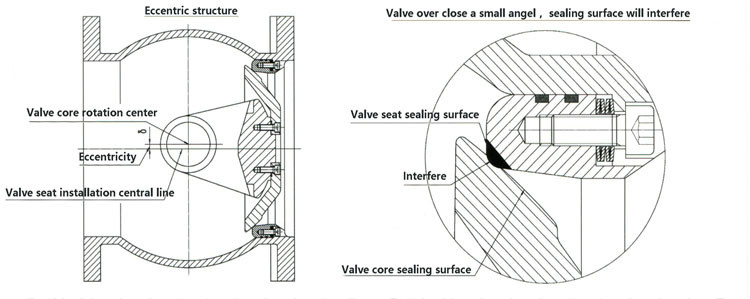

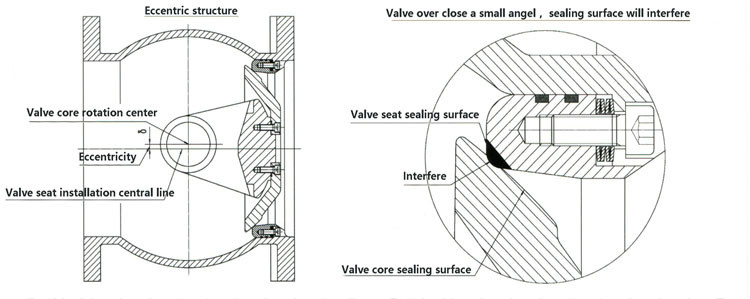

C. The valve can achieve zero-leakage (when forward and reverse "withstand 1.5 times of rated nominal pressure, valve achieves zero leakage), valve adopts eccentric structure, that is valve core rotation center and valve seat installation center has an eccentricity 6 (see below image). When the valve is fully dosed,if close a small angle more (such as 0.5°), the valve seat sealing surface and the valve core sealing surface will interfere, that is, between the two sealing surface will have a great squeezing force, forming a high Sealing pressure ratio, to achieve strict sealing. Valve eccentricity 5 value is determined by arigorous theoretical calculation (hydraulic calculation, eccentric shaft bending stiffness, torsional stiffness calculation, the crown and the valve seat deformation calculation), and not less than 20 tests, to meet the valve two-way sealing requirements.

D. Sealing surface will not be worn

Due to the eccentric structure,and eccentricity take full account of the hydraulic characteristics of the fluid and the mechanical properties of the material, when valve opens, valve core turned a small angle (such as 0.5 °), the valve core will leave valve seat sealing surface, when the valve is closing, the valve core and valve seat contact each other at the last moment, thereby reducing abrasion.

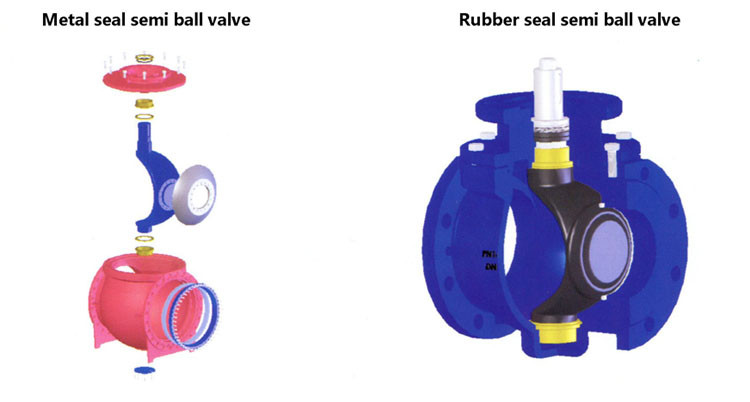

When valve is fully open, the valve core sealing surface "hidden" in the valve body, not directly scoured by the fluid. Metal seal valve sealing surface adopts stainless steel laser quenching process, the valve seat sealing surface using pure nickel welding process, the two materials with a reasonable hardness, run-in good,resistance to strong erosion.

Metal seal valve seat could float in a certain range, can compensate the abrasion error of processing,assembly. Rubber seal valve is fully coated with NBR, anti-abrasion,anti-corrosion

E. Sealing surface has the ability of self-clean.

The valve can shear off deposit dirt near the sealing surface each time when valve is closing

F. Valve structure is compact,easy to operate, easy to assemble and disassemble, easy to maintain, Smaller form factor. Size is small.

Valve is composed by valve body,bonnet, seat, eccentric crankshaft and sealing parts and others, a small number of parts, compact structure.

Valve structure length,installation height and other dimensions are smaller than gate valve, globe valve and other valves.

Valves can be on-line maintained, that is without removing valve from pipe line, remove the bonnet bolts, remove the bonnet, we can replace any parts inside valve.