Parameters

Nominal Diameter | 300-6000mm |

Nominal Pressure | 0.6 | 1.0 | 1.6 | 2.5 | MPa |

Seal Test Pressure | 0.66 | 1.1 | 1.76 | 2.75 |

Strength Test Pressure | 0.9 | 1.5 | 2.4 | 3.75 |

Medium Temperature | +5℃~+60℃ |

Suitable Medium | Water |

Valve Open Time | 60-120s Adjustable |

Valve Close Time | Close 65%-90% within 60s(Adjustable), Fully closed within 90-240s( Adjustable) |

Hydraulic System Max Pressure | 16.0MPa |

Leakage | 0 |

Flow Resistance Coefficient | ≤0.09 |

Material

| Name | Material |

Main Valve Body | Valve Body | Carbon Steel Q345 |

Disc | Carbon Steel Q345 |

Stem | 45# Steel( surfacing anti-corrosion treatment) or Stainless Steel 2Cr13 |

Dynamic Sealing Ring | Stainless Steel 1Cr18Ni9Ti |

Static Sealing Ring | Ductile Iron Surfacing CrCow |

Bypass Valve | Valve Body,Valve Core | Cast Steel WCB |

Sealing Surface | Stainless Steel 1Cr18Ni9Ti |

Stem | Stainless Steel 2Cr13 |

Expansion Joint | Expansion Seat | Cast Steel WCB |

Expansion Pipe | Carbon Steel Q345 |

Turbine set inlet hydraulic butterfly valve is generally used at the entrance of hydropower station or pumped storage power station turbine set with water head higher than 250M. the whole valve set includes upstream and downstream connecting pipe, valve body, expansion joints, bypass valve, exhaust valve, etc., Design in line with GB / T14478-1993 "large medium-sized turbine inlet valve basic technical conditions" requirement. Its role is:

1, When a main water supply pipe supplies water to several turbine sets, one of them need to be inspected and repaired, to cut off the flow without affecting the operation of other units.

2, When meeting with turbine set speed system accident, the turbine set speed increases to set value, the valve will be emergency shut down to prevent the accident from expanding.

3, When the turbine set stopped working for a long time, to cut off the upstream water, in order to reduce the guide vane leakage, to prevent the unit peristalsis.

1, The valve is suitable for a wide range of water head, the max water head is up to 1000 meters.

2, After the valve is fully open, the flow path is full diameter straight flow type, the hydraulic loss is small, no cavitation damage when working.

3, Valve closing is light, you can achieve zero leakage standards.

4, Valve is equipped with a working seal and inspection/ repairing seal, When inspection and repairing seal works, we could inspect and repair working seal and shaft end seal, without venting the water in pressure pipe before valve. When inspection and repairing seal works, the valve is equipped with hydraulic locking and manual locking, to ensure absolute safety during maintenance. The valve does not need to install a special repair valve, can save the project investment costs.

5, The hydraulic system uses energy storage tank technology, In the case of emergency power failure, the valve will be closed, to ensure the safety of whole turbine set system.

6, Uses self-regulating shaft seal; uses lead-free self-lubricating bearings. The seal box and shaft end supports are designed as components that are mounted outside the valve flow path, easy to disassemble and repair.

7, PLC programmable logic controller can be used as the electrical control part, to greatly simplify the electrical circuit and according to different working condition requirements, only need to change the program, do not need to change the line, with high versatility. At the same time, the use of PLC makes the valve has self-diagnostic function, and easy to connect to central control room computer.

8, Valve has automatic clean function to the weeds, mud, dirt and other dirt attached in the valve sealing surface. Sealing surface service life is long.

Working procedure

1 Open Valve

Open bypass valve--Release hydraulic lock--Release working seal--Fully open main valve core--Close bypass valve

2 Close Valve

Fully close main valve core-- Working seal works-- Hydraulic lock works

Working Principle

1. Open valve: start oil pump motor set, oil pump transfers pressure oil into the storage tank to the rated pressure and then stop. Open the bypass valve, water flows into shell, the exhaust valve will automatically exhaust. When the main valve inlet and outlet pressure difference reaches the set value, the hydraulic lock solenoid valve will work, lock release, work seal oil pressure will also release. At this point the valve open solenoid valve will work, the pressure oil is transferred into the main oil cylinder rodless chamber, the piston rod drives the valve shaft to rotate, the main valve core will rotate 90 ° to fully open. Close the bypass valve.

2. Close Valve: Close valve solenoid valve will work, the pressure oil is transferred into the main oil cylinder rod chamber, the main oil cylinder rodless chamber will drain, valve core closed. And then working seal works, the hydraulic lock solenoid valve will work, hydraulic locking works.

3. In the process of closing valve, the operating procedures are controlled by linkage signal, valve open and close time can be adjusted by the adjusting and controlling valve in hydraulic circuit.

0.6MPa

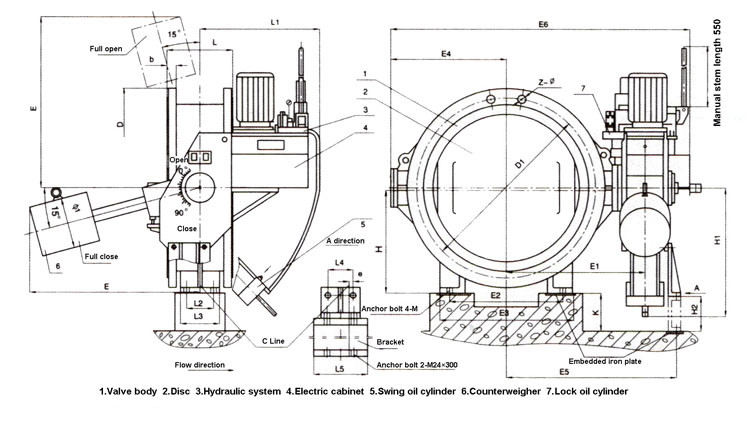

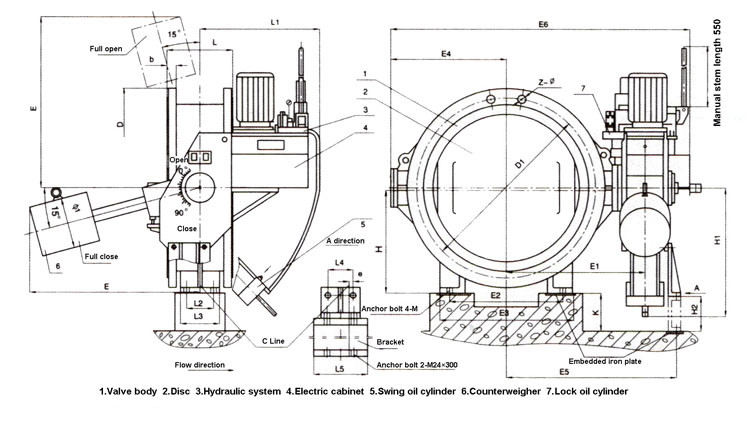

DN (mm) | D | D1 | b | L | L1 | L2 | L3 | L4 | L5 | E | E1 | E2 | E3 | E4 | E5 | E6 | Z-φ | φ1 | H | H1 | H2 | K | Motor Power (KW) | Anchor Bolts | Weight (kg) |

1000 | 1175 | 1120 | 26 | 550 | 930 | 200 | 360 | 245 | 335 | 1442 | 1105 | 740 | 830 | 765 | 1375 | 2450 | 28-30 | 620 | 620 | 1087 | 430 | 550 | 5.5 | 4-M30 | 3500 |

1200 | 1405 | 1340 | 28 | 630 | 970 | 260 | 420 | 245 | 335 | 1450 | 1224 | 790 | 945 | 850 | 1505 | 2600 | 32-33 | 620 | 710 | 1060 | 385 | 425 | 5.5 | 4-M30 | 4200 |

1250 | 1455 | 1390 | 30 | 630 | 970 | 260 | 420 | 245 | 335 | 1442 | 1250 | 790 | 970 | 900 | 1520 | 2720 | 32-33 | 620 | 800 | 1087 | 415 | 350 | 7.5 | 4-M30 | 5000 |

1400 | 1630 | 1560 | 32 | 710 | 1010 | 260 | 500 | 245 | 335 | 1450 | 1318 | 840 | 960 | 960 | 1597 | 2800 | 36-36 | 620 | 820 | 1060 | 385 | 300 | 5.5 | 4-M30 | 5900 |

1600 | 1830 | 1760 | 34 | 790 | 1050 | 260 | 540 | 245 | 335 | 1450 | 1418 | 960 | 1080 | 1070 | 1698 | 3140 | 40-36 | 620 | 920 | 1060 | 385 | 200 | 5.5 | 4-M36 | 7500 |

1750 | 1995 | 1920 | 36 | 870 | 1070 | 270 | 450 | 245 | 335 | 1890 | 1575 | 1350 | 1500 | 1215 | 1845 | 3445 | 44-39 | 760 | 1070 | 1250 | 450 | 265 | 7.5 | 4-M46 | 8500 |

1800 | 2045 | 1970 | 36 | 870 | 1090 | 270 | 450 | 245 | 335 | 1890 | 1600 | 1370 | 1510 | 1220 | 1869 | 3500 | 44-39 | 642 | 1035 | 1060 | 395 | 100 | 7.5 | 4-M39 | 9000 |

2000 | 2265 | 2180 | 38 | 950 | 1160 | 360 | 590 | 245 | 335 | 1890 | 1855 | 1370 | 1650 | 1380 | 2140 | 3750 | 48-42 | 760 | 1150 | 1250 | 450 | 200 | 7.5 | 4-M36 | 11600 |

2200 | 2475 | 2390 | 42 | 800 | 1160 | 500 | 790 | 245 | 335 | 1890 | 1927 | 1600 | 1900 | 1556 | 2242 | 4120 | 52-42 | 760 | 1360 | 1250 | 450 | 410 | 7.5 | 4-M36 | 12000 |

2250 | 2620 | 2490 | 55 | 860 | 1190 | 600 | 840 | 300 | 390 | 1891 | 1939 | 1600 | 1880 | 1630 | 2283 | 4235 | 52-52 | 800 | 1380 | 1292 | 255 | 200 | 7.5 | 4-M24 | 14050 |

2400 | 2685 | 2600 | 44 | 980 | 1160 | 500 | 800 | 245 | 335 | 1890 | 2088 | 2040 | 2250 | 1710 | 2400 | 4500 | 56-42 | 760 | 1380 | 1250 | 450 | 397 | 7.5 | 4-M36 | 14050 |

2500 | 2800 | 2700 | 50 | 980 | 1260 | 360 | 800 | 245 | 335 | 2168 | 2080 | 2000 | 2280 | 1710 | 2367 | 4320 | 56-48 | 760 | 1450 | 1250 | 705 | 100 | 7.5 | 4-M36 | 15000 |

2800 | 3115 | 3020 | 48 | 880 | 970 | 620 | 870 | 300 | 390 | 2168 | 2064 | 2350 | 2670 | 2010 | 2640 | 4900 | 64-42 | 780 | 1700 | 1428 | 450 | 172 | 7.5 | 4-M42 | 19000 |

3200 | 3535 | 3430 | 60 | 980 | | 600 | 960 | 300 | 390 | 1890 | 2469 | 2550 | 2800 | 2830 | 2813 | 5660 | 72-48 | 860 | 2020 | 100 | | 705 | 11 | 4-M42 | 33500 |

4000 | 4425 | 4300 | 80 | 1200 | | 750 | 1160 | 450 | 600 | 2200 | 3000 | 3300 | 3600 | 3420 | 3375 | 7000 | 84-62 | 1100 | 2000 | 400 | | 915 | 15 | 4-M42 | 55000 |

4800 | 5280 | 5100 | 80 | 1400 | | 1000 | 1360 | 450 | 600 | 2485 | 3380 | 3900 | 4300 | 3950 | 3910 | 7900 | 102-62 | 1100 | 2750 | 250 | | 1290 | 15 | 4-M42 | 80000 |

1.0MPa

DN (mm) | D | D1 | b | L | L1 | L2 | L3 | L4 | L5 | E | E1 | E2 | E3 | E4 | E5 | E6 | Z-0 | 01 | H | H1 | H2 | K | Motor Power (KW ) | Anchor Bolts | Weight (kg) |

1000 | 1230 | 1160 | 34 | 550 | 920 | 200 | 360 | 245 | 335 | 1450 | 1106 | 740 | 830 | 740 | 1354 | 2400 | 28-36 | 620 | 620 | 1060 | 460 | 500 | 5.5 | 4-M30 | 3850 |

1200 | 1455 | 1380 | 38 | 630 | 970 | 260 | 440 | 245 | 335 | 1450 | 1224 | 790 | 940 | 850 | 1464 | 2600 | 32-39 | 620 | 740 | 1060 | 370 | 410 | 5.5 | 4-M36 | 4800 |

1250 | 1510 | 1430 | 42 | 630 | 970 | 260 | 420 | 245 | 335 | 1442 | 1250 | 790 | 970 | 900 | 1520 | 2720 | 32-39 | 620 | 800 | 1087 | 415 | 350 | 5.5 | 4-M36 | 5000 |

1400 | 1675 | 1590 | 42 | 710 | 1010 | 260 | 400 | 245 | 335 | 1885 | 1214 | 840 | 960 | 1135 | 1493 | 2800 | 36-42 | 642 | 850 | 1060 | 385 | 270 | 5.5 | 4-M36 | 6700 |

1600 | 1915 | 1820 | 46 | 790 | 1080 | 270 | 500 | 245 | 335 | 1890 | 1570 | 960 | 1100 | 1140 | 1857 | 3200 | 40-48 | 760 | 970 | 1250 | 450 | 350 | 5.5 | 4-M36 | 8400 |

1750 | 2100 | 1950 | 50 | 870 | 1070 | 270 | 450 | 245 | 335 | 1890 | 1690 | 1350 | 1560 | 1270 | 2005 | 3340 | 48-45 | 760 | 1070 | 1250 | 450 | 250 | 7.5 | 4-M36 | 9100 |

1800 | 2115 | 2020 | 50 | 870 | 1120 | 440 | 860 | 245 | 335 | 1890 | 1710 | 1370 | 1600 | 1320 | 1995 | 3500 | 44-48 | 760 | 1100 | 1250 | 450 | 220 | 7.5 | 4-M36 | 9800 |

2000 | 2325 | 2230 | 54 | 950 | 1160 | 460 | 640 | 245 | 335 | 1890 | 1790 | 1400 | 1700 | 1460 | 1420 | 2150 | 48 - 48 | 760 | 1200 | 1250 | 537 | 220 | 7.5 | 4-M36 | 12800 |

2200 | 2550 | 2440 | 58 | 800 | 1160 | 500 | 780 | 300 | 390 | 1891 | 1929 | 1560 | 1750 | 1600 | 2273 | 4195 | 52-52 | 800 | 1450 | 1292 | 370 | 200 | 7.5 | 4-M36 | 13000 |

2250 | 2620 | 2490 | 60 | 980 | 1170 | 400 | 600 | 300 | 390 | 1890 | 1979 | 1600 | 1880 | 1496 | 2290 | 4100 | 52-56 | 1000 | 1380 | 1250 | 600 | 80 | 7.5 | 4-M36 | 13400 |

2400 | 2760 | 2650 | 60 | 980 | 1160 | 450 | 650 | 300 | 390 | 1891 | 2024 | 1800 | 2100 | 1650 | 2368 | 4410 | 56-56 | 800 | 1600 | 1436 | 475 | 100 | 7.5 | 4-M36 | 15900 |

2500 | 2865 | 2750 | 60 | 980 | 1160 | 700 | 970 | 300 | 390 | 2155 | 1969 | 2000 | 2280 | 1750 | 2313 | 4455 | 56-56 | 860 | 1550 | 1428 | 250 | 150 | 7.5 | 4-M36 | 16000 |

2600 | 2960 | 2850 | 60 | 980 | 1160 | 800 | 990 | 300 | 390 | 2168 | 2159 | 2150 | 2470 | 1855 | 2505 | 4660 | 60-52 | 780 | 1555 | 1436 | 220 | 140 | 7.5 | 4-M36 | 20000 |

3000 | 3405 | 3220 | 60 | 980 | 1160 | 620 | 980 | 300 | 390 | 2155 | 2384 | 2550 | 2800 | 2010 | 2728 | 4838 | 68 - 56 | 860 | 1900 | 250 | 580 | 100 | 7.5 | 6-M42 | 24000 |

3500 | 3950 | 3810 | 70 | 980 | | 600 | 980 | 300 | 390 | 1860 | 2784 | 3000 | 3300 | 3082 | 3128 | 6397 | 60-62 | 860 | 2180 | 250 | | 1020 | 11 | 6-M42 | 36500 |

3600 | 4005 | 3890 | 80 | 1200 | | 800 | 1170 | 300 | 390 | 1860 | 2724 | 2800 | 3200 | 3030 | 3068 | 6200 | 72-62 | 860 | 2250 | 250 | | 1090 | 11 | 6-M42 | 37000 |

3800 | 4250 | 4120 | 80 | 1200 | | 750 | 1160 | 300 | 390 | 1860 | 2824 | 3300 | 3600 | 3122 | 3168 | 6300 | 72-62 | 860 | 2150 | 250 | | 980 | 11 | 6—M42 | 38000 |

4200 | 4615 | 4500 | 80 | 1300 | | 900 | 1260 | 450 | 600 | 2485 | 3130 | 3200 | 3600 | 3515 | 3660 | 7410 | 88-62 | 1100 | 2560 | 250 | | 1060 | 15 | 6-M42 | 65000 |

4400 | 4880 | 4700 | 80 | 1400 | | 1000 | 1380 | 450 | 600 | 2485 | 3180 | 3700 | 4000 | 3730 | 3710 | 7460 | 88-56 | 1100 | 2400 | 250 | | 885 | 15 | 6-M42 | 67000 |

5300 | 5730 | 5600 | 80 | 1400 | | 950 | 1410 | 500 | 620 | 2518 | 3415 | 4030 | 4330 | | 3415 | | 120-65 | | | | | | 22 | | 120000 |

1.6MPa

DN (mm) | D | D1 | b | L | L1 | L2 | L3 | L4 | L5 | E | E1 | E2 | E3 | E4 | E5 | E6 | Z-0 | 01 | H | H1 | H2 | K | Motor Power (KW ) | Anchor Bolts | Weight (kg ) |

1000 | 1255 | 1170 | 42 | 550 | 950 | 200 | 360 | 245 | 335 | 1450 | 1120 | 740 | 830 | 765 | 1388 | 2470 | 28-42 | 620 | 640 | 1087 | 380 | 480 | 5.5 | 4-M30 | 4500 |

1200 | 1485 | 1390 | 48 | 630 | 990 | 260 | 420 | 245 | 335 | 1450 | 1220 | 790 | 945 | 890 | 1496 | 2660 | 32-48 | 620 | 760 | 1087 | 400 | 380 | 5.5 | 4-M30 | 5200 |

1250 | 1540 | 1440 | 52 | 630 | 990 | 260 | 420 | 245 | 335 | 1450 | 1230 | 790 | 930 | 980 | 1595 | 2810 | 32-48 | 620 | 800 | 1087 | 450 | 385 | 7.5 | 4-M30 | 5800 |

1400 | 1685 | 1590 | 52 | 710 | 1050 | 320 | 480 | 245 | 335 | 1890 | 1410 | 900 | 1020 | 1060 | 1680 | 2960 | 36-48 | 620 | 900 | 1070 | 470 | 305 | 7.5 | 4-M30 | 7100 |

1600 | 1930 | 1820 | 58 | 790 | 1100 | 270 | 500 | 245 | 335 | 1890 | 1525 | 1100 | 1300 | 1230 | 1805 | 3300 | 40-56 | 760 | 1050 | 1237 | 455 | 275 | 7.5 | 4-M36 | 8500 |

1750 | 2080 | 1970 | 60 | 870 | 1130 | 360 | 560 | 300 | 390 | 1900 | 1692 | 1380 | 1600 | 1365 | 2036 | 3630 | 44-56 | 800 | 1100 | 1292 | 85 | 270 | 7.5 | 4-M36 | 9300 |

1800 | 2130 | 2020 | 62 | 870 | 1130 | 270 | 450 | 300 | 390 | 1900 | 1729 | 1370 | 1510 | 1320 | 2073 | 3630 | 44-56 | 800 | 1100 | 1292 | 85 | 270 | 7.5 | 4-M36 | 9500 |

2000 | 2345 | 2230 | 66 | 850 | 1130 | 500 | 810 | 300 | 390 | 2160 | 1814 | 1700 | 2000 | 1490 | 2158 | 3800 | 48-62 | 860 | 1250 | 1436 | 80 | 258 | 7.5 | 4-M36 | 9800 |

2250 | 2620 | 2490 | 70 | 860 | 1130 | 600 | 850 | 300 | 390 | 2160 | 1979 | 1600 | 1880 | 1630 | 2323 | 4220 | 52-62 | 860 | 1380 | 1436 | 80 | 125 | 7.5 | 4-M36 | 10000 |

2500 | 2865 | 2750 | 70 | 980 | 1300 | 700 | 970 | 300 | 390 | 2160 | 2109 | 2000 | 2280 | 2500 | 2453 | 5000 | 56-56 | 860 | 1650 | 100 | | 325 | 11 | 4-M42 | 26000 |

3000 | 3410 | 3290 | 80 | 980 | 1300 | 620 | 980 | 300 | 390 | 2160 | 2469 | 2550 | 2800 | 2860 | 2813 | 5720 | 68-62 | 860 | 1900 | 100 | | 575 | 11 | 4-M42 | 30000 |

3200 | 3625 | 3500 | 80 | 980 | 1300 | 600 | 960 | 300 | 390 | 1890 | 2469 | 2550 | 2800 | 2830 | 2813 | 5660 | 72-62 | 860 | 2020 | 100 | | 705 | 11 | 4-M42 | 32000 |